Manufacturing

Cranes

We manufacture as well as customize cranes for all types of application and usage scenarios. No facility is going to be a universal fit for one type of crane, but some of out most popular options include:

Jib cranes are best used in fixed locations where concrete work may be required. Capacities range from 100 Ibs. to 10,000 Ibs. with boom lengths to 30' (longer lengths are available). Motorized and articulating options are also available.

Typical Designs

- Base Mount Jib (BMJ)

- Mast Cantilever Jib (MCJ)

- Cantilever Wall Mounted Jib (WCJ)

- Tie-Rod Wall Mounted Jib (WBJ)

- Spreader Beams

- Manipulating Crane

- Plate Grabber

- Rotating Hook Configurations

- B.O.P. Offshore Cranes

Transfer Carts

A Transfer Cart is a cost-effective material transport skid that is often used in warehouses, fabrication shops and manufacturing plants. It can be used in conjunction with gantry and overhead cranes to move heavy loads across the bridge. Transfer carts are not complex devices and operate on floors with a moveable or permanent installation.

At Osborn Technical Services, we offer a wide variety of Transfer carts. Our principal design is very compact, quiet, user-friendly, and easy to maintain. OTS transfer carts are ideal when a forklift isn’t feasible and are available in battery, electric, and AC/DC powered, or manual push/pull.

Custom Conveyors

When a standard conveyor system won’t fit your application requirements, we can create custom conveyors to suit your needs.

We can design and fabricate standard chain enclosed track, power and free, I-beam, and belt conveyors.

Our electric-powered conveyors can be equipped with adjustable speed for different products. In some applications, we can even move a complete system out of the way for maintenance or repairs on machinery that may be below the conveyor.

Containment Testing Shelters

Containment test shelters are designed to protect and shield your facility during a high-pressure test of valves or equipment and can contain any failure that may occur. We design our shelters to ensure that any fragments are diffused, preventing any bodily harm or property damage.

Osborn offers 100% containment or an open-style roof design. Open style configurations do not have a roof and you have the ease of access when loading and unloading with an overhead crane above the shelter. Additional features that can be incorporated into the design include:

- Manual or auto door locks

- Liquid recycling

- Remote surveillance

- Recording capabilites

- Overhead or jib cranes inside the unit

- Lighting

Custom-built Hoist, Trolley, and End-Trucks

Our custom-built hoist, trolley, and bridge end trucks are designed for heavy-duty applications. Our equipment is very easy to work on which makes routine maintenance simple. All custom components are designed to meet and often exceed your requirements.

Vertical Traveling Platforms

At Osborn we offer a wide variety of platform designs, you can choose from our standard units, or We can also engineer a complete system with a covered canopy complete with a mezzanine and stairway. The common range of vertical travel is 10’ to 14′ on most tank trucks and 10′ to 22′ on railcars. However, we can accommodate almost any range as required.

Osborn is the leader in the design, engineering, and manufacturing of loading and inspection platforms for tank trucks and railcars. When it comes to shipping, we understand that time and safety mean money.

When it comes to loading and inspections, excellence is judged in hours, minutes, and safe accurate loading conditions. No matter how large or small the loading and inspection facility, Osborn can provide a platform solution for your maximum efficiency including corrosive and hazardous environments. Our platforms are so dependable we have many platforms are still in operation since the 1980s

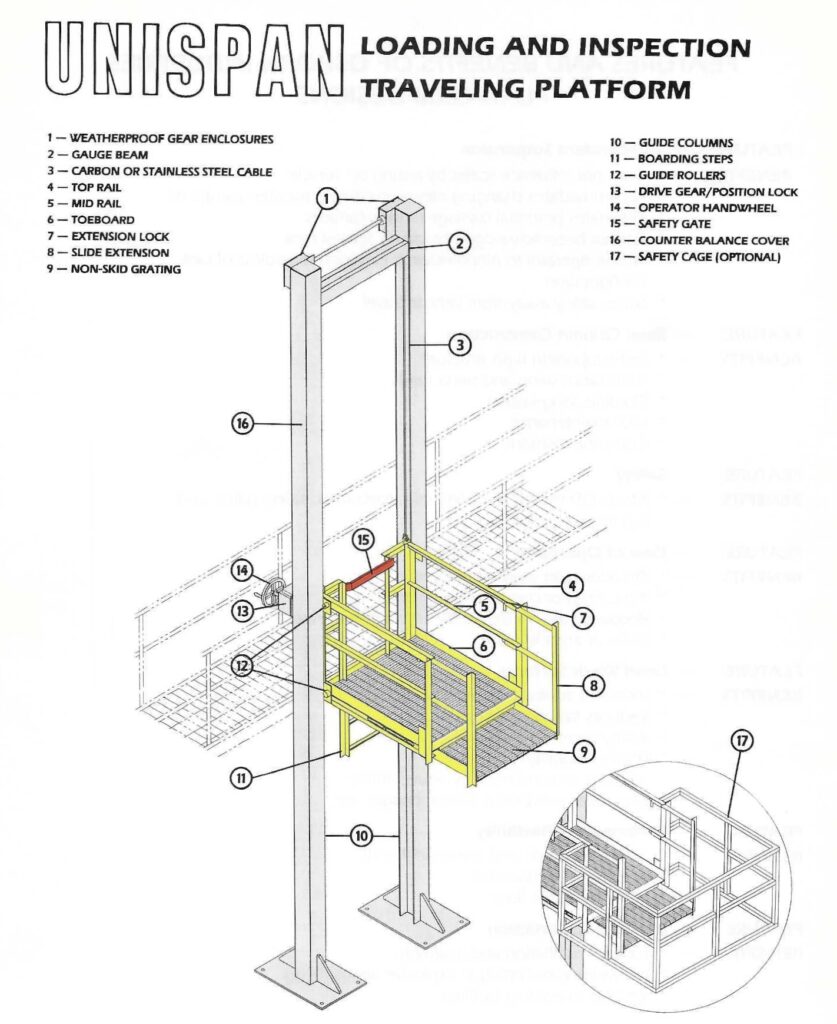

Unispan

A typical galvanized Platform size is 3’wide x 4’ with or without a sliding deck extension to accommodate truck and railcars of any shape or size. Typically mounted on a self-supporting rigid structure or it can be tied into an existing structure if capable. Vertical control options are usually manual, but there is the option of electric or pneumatic air if you desire. An enclosed safety cage is another additional safety feature for extreme working conditions.

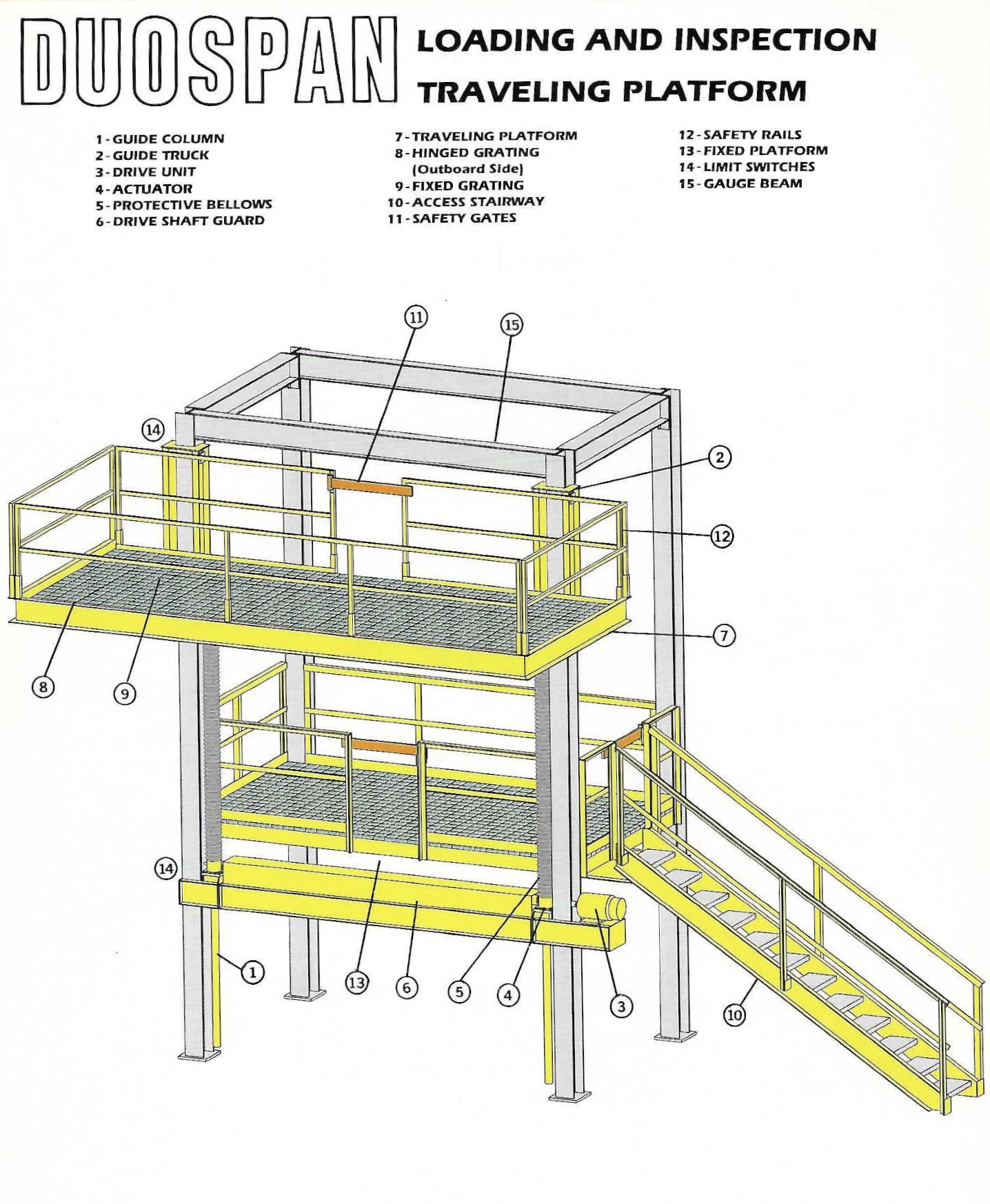

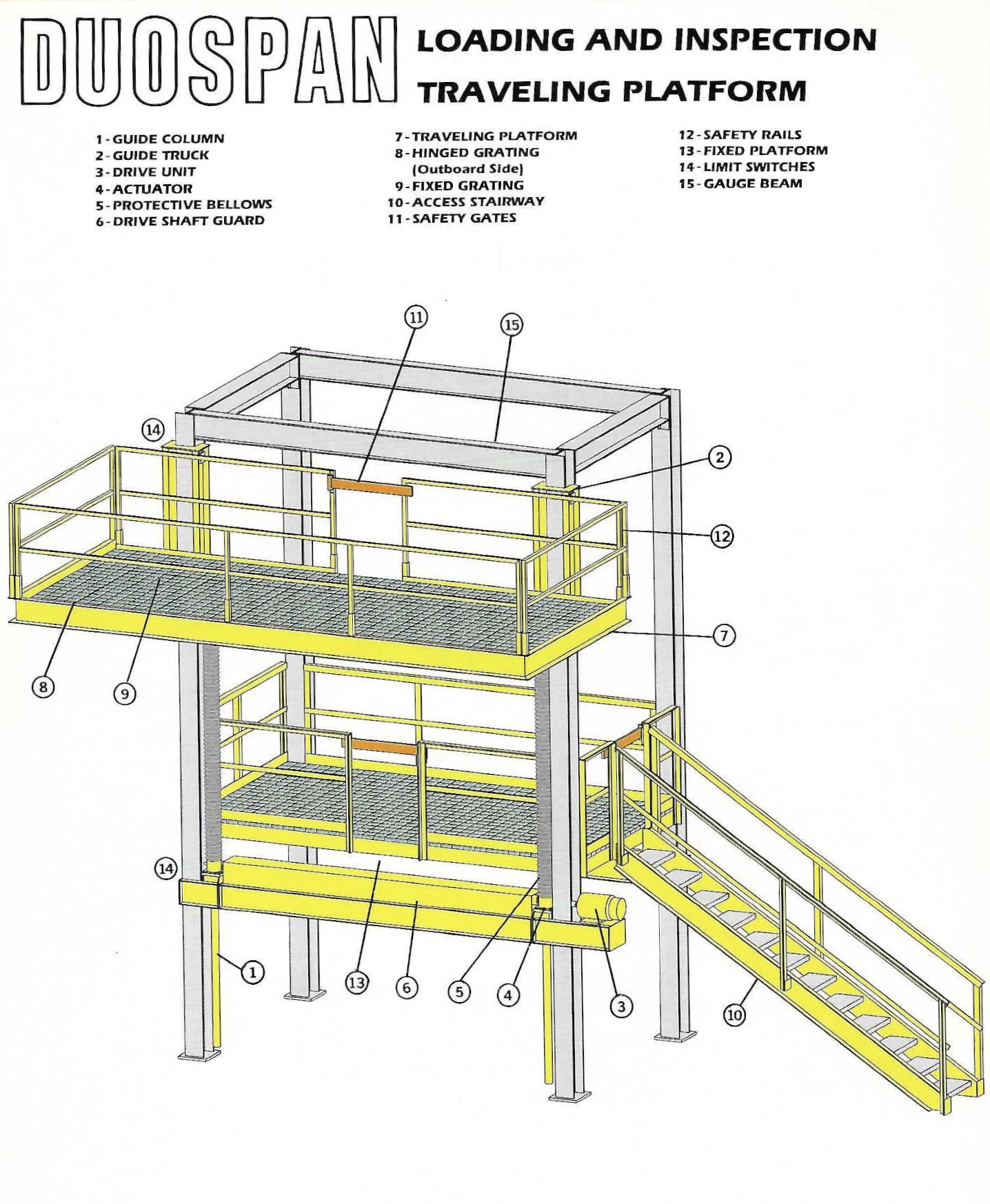

Duospan

The Osborn Duospan is compact cantilever traveling platform system utilizing two structural steel support and guider columns. The Duospan is ideally suited for retrofit applications or where space conditions for traffic access may be restricted. The Duospan Is the answer to tough confined areas and moderztion of existing loading facilities.

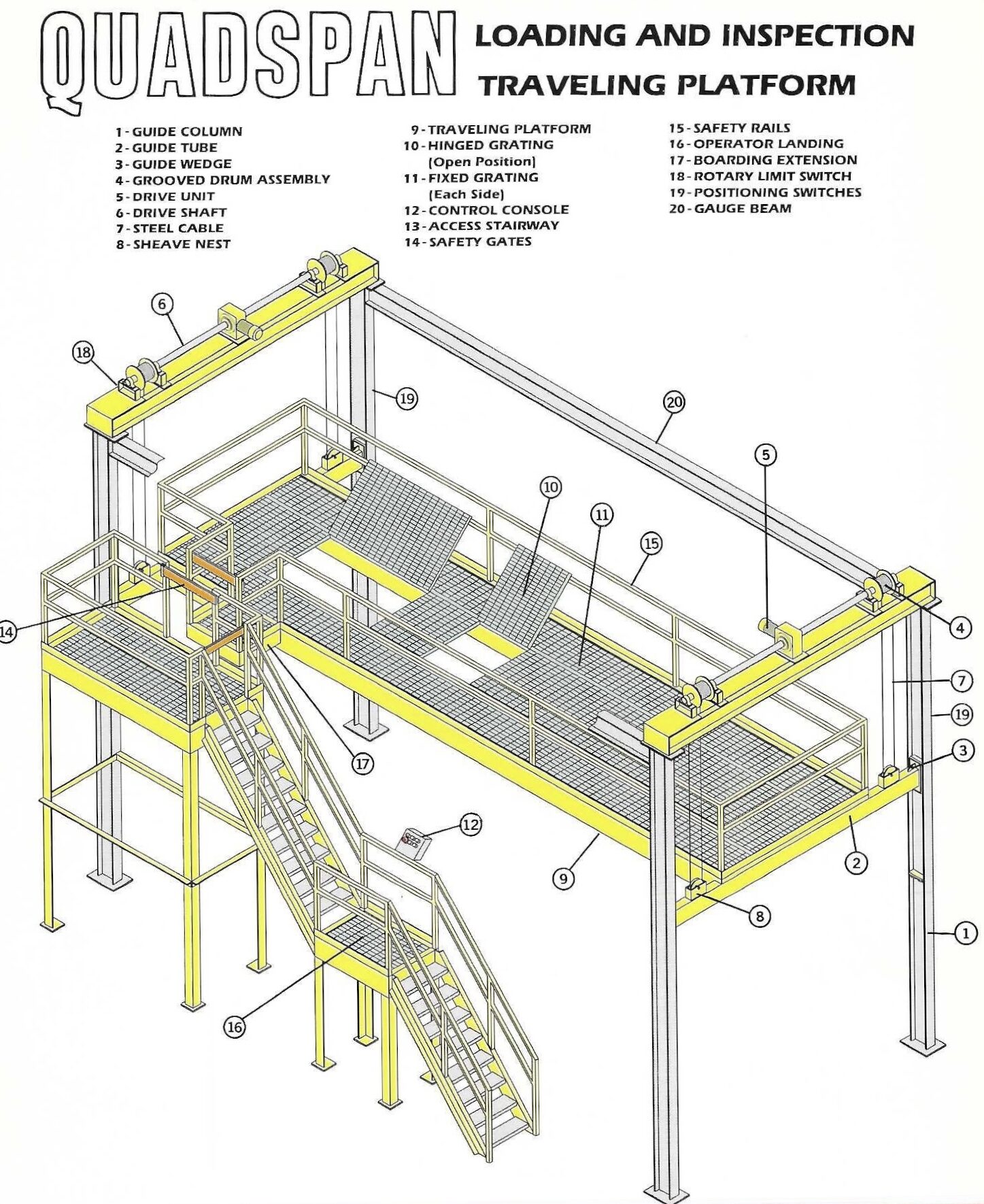

Quadspan

The Quadspan is a self-supporting traveling platform system housed whining a four-column steel structure. The steel columns serve as structural supports as well as an integral, anti-sway guide system for traveling platform. The Quadspan is versatile and can be constructed in multiples to accommodate several vehicles at one time to speed the loading process.

Drive System Technology for Quadspan and Duospan

You can choose from two types of drive packages to power your Osborn platform. These packages are in various configurations and allow unlimited design approaches to meet your loading and inspection center requirements. Osborn drive packages allow operators to precisely potion the platform at any location within the operating range.

The “Cable Drum Package” is provided with multiple drums that are accurately machined and grooved. Unlimited lifting heights are available for any clearance requirements. Fast acting, self-energized brakes automatically engage to assure controlled shut-down.

The “Actuator Package” utilizes multiple machine screw actuators which are self-locking and will maintain platform position in the event of a power failure. The Power Actuator package is available with a wide range of lifting heights and is ideally suited for limited space applications.

Winches

Our heavy-duty electric winches can handle a wide range of solutions from lifting, pulling, or positioning loads with ease. Our dependable winches come built for longevity and durability. Standard configurations include:

- Solid carbon steel/stainless steel drum and shafts

- Load holding motor disc brakes

- Direct drive gear reducers

- Flange style roller bearing

- Stationary push button with remote control operations

- Warning lights and horn

- 3-step epoxy paint coatings

Inspection and Preventative Maintenance Services

The goal of Osborn Technical Services Preventative Maintenance and Load Testing is crucial to improving safety and productivity. Regular inspections and preventive maintenance activities help to detect wear and tear on parts and equipment before a critical failure occurs. Regular service and repairs ensure a safe and productive operation.

Osborn Technical Services engineers conduct a series of tests to ensure all crane functions are working properly under a load. Cranes are tested at a minimum of 100% to 125% maximum of their capacity. Load testing is to ensure your employees are safe knowing the equipment is safe to handle a load within the crane’s rated capacity.

Osborn Technical Services service technicians offer scheduled service and repairs to minimize production loss. When your primary equipment breaks down, we have the expertise to get you back in operation with minimal downtime.

We offer emergency 24/7 service calls for prompt service. With our in-house machine shop, we don’t need to outsource any machine work, which makes for a faster turnaround time for quick repairs.

Our services technicians are trained to work safe at your facility. We adhere to all workplace safety standards and are a trusted member of the following safety councils:

- Brazosport Safety Council

- Houston Area Contractor Safety Council

- Industrial Safety Training Council

We can install a complete turnkey package from crane runways, overhead cranes, and vertical traveling platforms, plus any type of custom fabricated equipment.

But what if your crane is old and outdated, doesn’t that make it obsolete? If your crane is structurally sound, why waste money replacing the entire rig? We can retrofit your old, outdated crane with the newest components extending its life for a fraction of what a new crane would cost.

Most of the older cranes were designed to last a lifetime but replacing drive components and variable frequency drives can help your crane last even longer. This leads to a lower risk of downtime and increased productivity.

Osborn Technical Services has the machining capability to handle most of your crane and custom machined parts needs such as:

- 24” swing manual lathe with a 5” thru spindle with 120” bed length

- 3 axis vertical mill 60”x 15” table with digital readout

- 3 axis vertical mill 80”x 16” table with rotary table

- Radial arm drill press

We also offer a wide range of hydraulic press capabilities. If you have a stubborn wheel, gear, bearing or any other shaft arrangement that needs to be removed or reassembled we are here to help.

- 200-ton horizontal wheel press dimensional capable of 5’ wide x 20’+

- 100-ton vertical wheel press dimensional capable of 34” wide x 54” +

- 30-ton vertical “C” frame press dimensional capable of 22” wide x 24” +

- 20-ton vertical wheel press dimensional capable of 24” wide x 48” +

Custom Fabrication

Our team is comprised of certified welders/fabricators with over 30 years of experience in carbon steel, stainless, and aluminum. We can help with design or work from your provided schematics and help you finish your project on time. We perform a wide range of custom fabrications including but not limited to:

- Pipe/Material Racks

- Tool Holders

- Oil Field Skids

- Motor Mount Base Plates Adapters

- Trailers

- Scissor Lift Tables

- Even Deer Blinds